Understanding Load Cells: The Essential Guide to Precision Weighing and Measurement Technology

In a world where precision matters, load cells play a pivotal role in various industries, transforming the way we measure weight and force. These sophisticated devices are essential for everything from industrial scales to high-tech medical equipment, ensuring accurate and reliable measurements. Understanding load cells is not just for engineers or industry professionals; it’s crucial for anyone involved in quality control, manufacturing, or logistics. This essential guide will delve into the mechanics behind load cells, exploring their types, applications, and how they contribute to precision weighing. Whether you’re looking to enhance your understanding of measurement technology or seeking solutions for your business, this guide will equip you with the knowledge you need to appreciate the vital role that load cells play in measurement accuracy and reliability. Join us as we unravel the intricacies of load cells and discover how they can elevate your operational efficiency and effectiveness.

What are Load Cells?

Load cells are transducers used to convert force or weight into an electrical signal. They are integral components in the realm of precision measurement, enabling a wide range of applications from weighing scales to industrial automation systems. Essentially, load cells are the backbone of modern weighing technology, providing the accuracy and reliability necessary for various industries to function efficiently. These devices come in different designs and capacities, each tailored to specific weighing needs and environments.

The basic principle behind a load cell is straightforward: it senses the force exerted on it and converts this force into an electrical signal that can be measured and displayed. The conversion process involves strain gauges, which are affixed to a load-bearing element. When force is applied, the strain gauges deform, altering their electrical resistance. This change in resistance is then measured and translated into a force or weight reading. This process allows for highly accurate measurements, which are essential in applications where precision is paramount.

Load cells are not just limited to simple weighing tasks. They play a crucial role in various complex systems where force measurement is required. From the aerospace industry to medical devices, load cells provide the necessary data to ensure processes are carried out correctly and safely. Their versatility and reliability make them indispensable tools in any sector that demands precise weight or force measurements.

The Importance of Load Cells in Weighing and Measurement

The significance of load cells in weighing and measurement cannot be overstated. In industries where accurate weight measurement is critical, such as pharmaceuticals, food and beverage, and manufacturing, load cells ensure that products meet stringent quality standards. They help maintain consistency, reduce waste, and enhance productivity by providing precise and reliable measurements. Without load cells, many of the processes we take for granted today would be far less efficient and more prone to errors.

In the medical field, for example, load cells are used in devices such as dialysis machines and infusion pumps, where exact measurements of fluid volumes are crucial for patient health. These applications demand the highest levels of precision, and load cells provide the necessary accuracy to ensure patient safety and effective treatment outcomes. Similarly, in the aerospace industry, load cells are used to measure the forces acting on various components, ensuring that aircraft operate safely within their design parameters.

Load cells also play a vital role in logistics and supply chain management. Accurate weighing of goods ensures that transportation vehicles are loaded within safe limits, preventing accidents and optimizing fuel efficiency. In retail, load cells are used in point-of-sale scales to ensure customers are charged accurately for their purchases. The reliability of these measurements directly impacts customer satisfaction and trust in the business.

Types of Load Cells and Their Applications

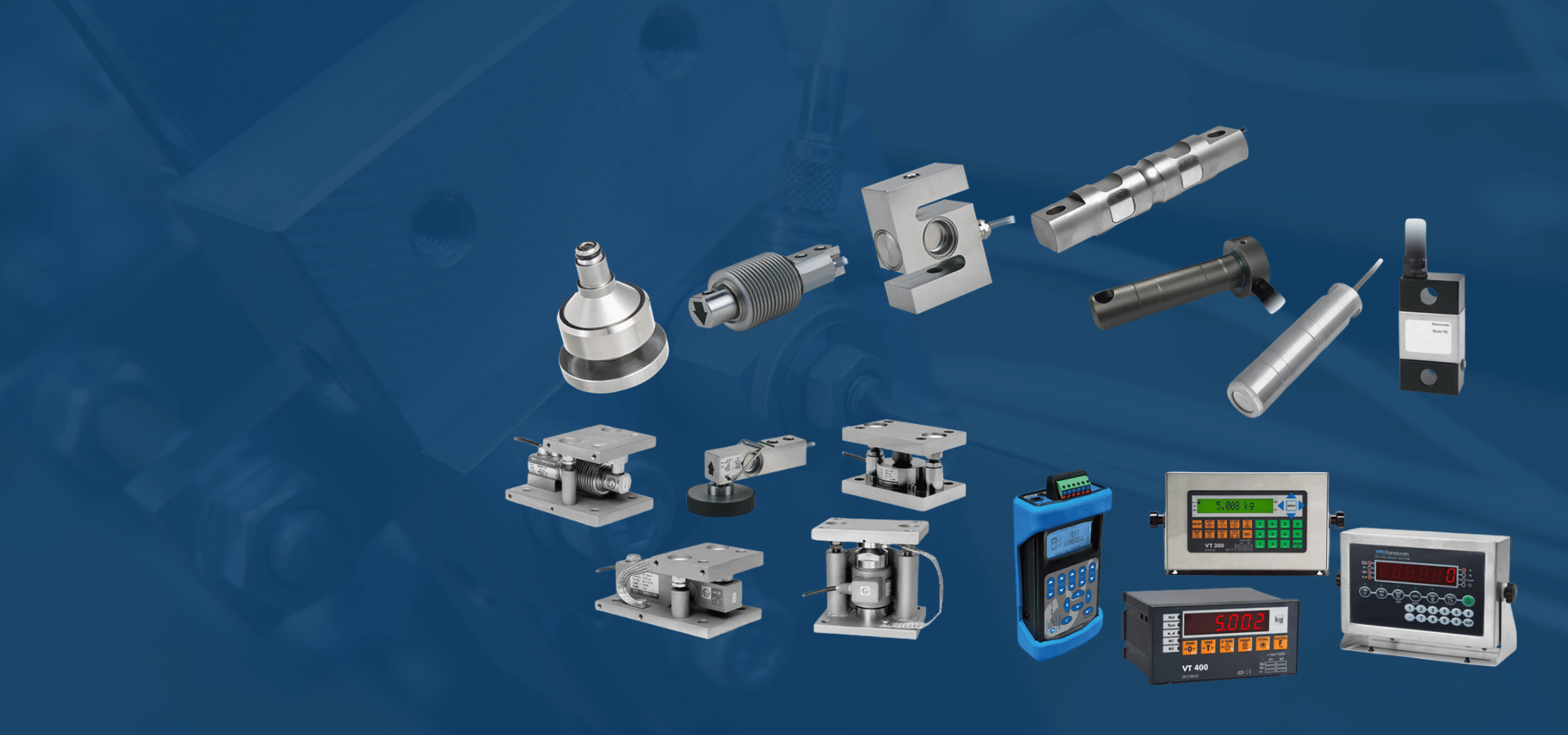

Load cells come in various types, each designed to meet specific measurement needs. The most common types include strain gauge load cells, hydraulic load cells, pneumatic load cells, and capacitive load cells. Each type has its unique advantages and is suited for different applications.

Strain gauge load cells are the most widely used type due to their high accuracy and versatility. They consist of a metal element with strain gauges attached to it. When a force is applied, the metal deforms, causing the strain gauges to change their resistance. This change is measured and converted into an electrical signal. Strain gauge load cells are used in a wide range of applications, from industrial scales to laboratory balances, due to their robustness and precision.

Hydraulic load cells operate on the principle of fluid pressure. When a force is applied to the load cell, it compresses a fluid within a chamber, creating pressure that is proportional to the applied force. This pressure is then measured and converted into a weight reading. Hydraulic load cells are commonly used in harsh environments where electrical load cells might fail, such as in heavy industrial applications or outdoor settings where conditions can be extreme.

Pneumatic load cells, similar to hydraulic load cells, use air pressure to measure force. They are often used in applications where safety is a concern, as they do not require electrical power and are intrinsically safe. Capacitive load cells measure changes in capacitance caused by the deformation of a load-bearing element. These load cells are highly sensitive and are used in applications where very small changes in force need to be measured, such as in laboratory equipment and precision manufacturing.

How Load Cells Work: The Science Behind Precision Measurement

The operation of load cells is grounded in fundamental principles of physics and engineering. At the heart of most load cells is the strain gauge, a device that measures the amount of deformation (strain) in a material. When a load or force is applied to the load cell, it causes a slight deformation in the material to which the strain gauge is attached. This deformation changes the electrical resistance of the strain gauge, and this change is measured and recorded as an electrical signal.

This electrical signal is typically very small and needs to be amplified before it can be used. An amplifier increases the strength of the signal, making it easier to process and analyze. The amplified signal is then sent to a display or data acquisition system, where it is converted into a readable format, such as weight or force. The entire process occurs in real-time, allowing for accurate and immediate measurements.

The precision of load cells is achieved through meticulous design and calibration. The materials used in load cells are carefully selected for their mechanical properties, ensuring that they can withstand the forces they are intended to measure without undergoing permanent deformation. The strain gauges are also precisely applied to ensure consistent and accurate readings. Calibration involves applying known weights to the load cell and adjusting the system to ensure that the output matches the applied weight accurately.

Advanced load cells incorporate additional technologies to enhance their performance. For example, some load cells use temperature compensation techniques to ensure accurate measurements across a range of temperatures. Others may include multiple strain gauges arranged in a specific configuration to measure forces in different directions or to improve sensitivity. These innovations make load cells incredibly versatile and capable of meeting the demands of a wide range of applications.

Key Factors to Consider When Choosing a Load Cell

Selecting the right load cell for a specific application involves considering several key factors. One of the most important considerations is the load capacity of the load cell, which refers to the maximum weight or force it can accurately measure. Choosing a load cell with an appropriate capacity is crucial for ensuring accurate measurements and preventing damage to the load cell.

The environment in which the load cell will be used is another critical factor. Load cells used in harsh or hazardous environments, such as industrial or outdoor settings, may need to be more robust and resistant to factors such as moisture, dust, and temperature fluctuations. In such cases, load cells with protective enclosures or those made from durable materials may be necessary to ensure reliable performance.

Accuracy and precision are also paramount when selecting a load cell. Different applications require different levels of precision, and it is important to choose a load cell that meets the required specifications. Factors such as the resolution, repeatability, and linearity of the load cell should be considered to ensure that it provides the necessary accuracy for the application.

Additionally, the type of load cell should be chosen based on the specific application requirements. For example, strain gauge load cells are suitable for a wide range of applications due to their high accuracy and versatility, while hydraulic or pneumatic load cells may be better suited for environments where electrical components are at risk of failure. The mounting and installation requirements of the load cell should also be considered, as these can impact the ease of use and integration into existing systems.

Load Cell Calibration: Ensuring Accuracy and Reliability

Calibration is a critical process in ensuring the accuracy and reliability of load cells. It involves comparing the output of the load cell to a known standard and making adjustments to ensure that the readings are accurate. Regular calibration is essential for maintaining the performance of load cells and ensuring that they provide precise measurements over time.

The calibration process typically involves applying known weights to the load cell and recording the output. This data is then used to create a calibration curve, which shows the relationship between the applied weight and the load cell’s output. Any deviations from the expected output are corrected by adjusting the load cell’s settings or by applying a calibration factor. This ensures that the load cell provides accurate readings across its entire range.

There are different methods of calibration, including static and dynamic calibration. Static calibration involves applying a series of known weights to the load cell and recording the output at each weight. Dynamic calibration, on the other hand, involves applying varying loads to the load cell in a controlled manner and recording the output. Both methods are effective, and the choice of method depends on the specific application and requirements.

Regular calibration is essential for maintaining the accuracy of load cells, especially in applications where precision is critical. Factors such as temperature changes, mechanical wear, and environmental conditions can affect the performance of load cells over time. By regularly calibrating load cells, these factors can be accounted for, ensuring that the load cells continue to provide accurate and reliable measurements.

Common Industries Utilizing Load Cells

Load cells are used in a wide range of industries, each relying on the precision and reliability of these devices for their specific applications. One of the most prominent industries utilizing load cells is the manufacturing sector. In manufacturing, load cells are used to monitor and control production processes, ensuring that products are made to exact specifications. They are used in weighing systems, force measurement applications, and material testing, among other uses.

The automotive industry also relies heavily on load cells for various applications. Load cells are used in vehicle testing and development to measure forces and loads on different components, ensuring that vehicles meet safety and performance standards. They are also used in assembly lines to monitor and control the production process, ensuring that each component is manufactured to precise specifications.

In the food and beverage industry, load cells are used in weighing and packaging systems to ensure that products are accurately weighed and packaged. This is crucial for maintaining product quality and consistency, as well as for meeting regulatory requirements. Load cells are used in a variety of applications, from weighing ingredients to measuring the weight of finished products.

The medical field is another industry that relies on load cells for precision measurement. Load cells are used in medical devices such as dialysis machines, infusion pumps, and patient weighing systems. These applications require the highest levels of accuracy and reliability, as they directly impact patient health and treatment outcomes.

Innovations and Trends in Load Cell Technology

The field of load cell technology is constantly evolving, with new innovations and trends emerging to meet the demands of modern applications. One of the most significant trends in load cell technology is the development of digital load cells. Unlike traditional analog load cells, digital load cells convert the measured force directly into a digital signal. This eliminates the need for amplifiers and reduces the potential for signal interference, resulting in more accurate and reliable measurements.

Another trend in load cell technology is the integration of wireless communication capabilities. Wireless load cells offer greater flexibility and ease of use, as they can be installed in locations where wiring is impractical or undesirable. They also enable remote monitoring and data collection, allowing for real-time analysis and control of processes. This is particularly useful in applications where load cells are used in hazardous or hard-to-reach environments.

The use of advanced materials and manufacturing techniques is also driving innovation in load cell technology. New materials, such as advanced composites and alloys, offer improved strength and durability, allowing load cells to withstand higher loads and harsher environments. Additive manufacturing techniques, such as 3D printing, are also being used to create load cell components with complex geometries and improved performance characteristics.

Artificial intelligence (AI) and machine learning are also making their way into load cell technology. These technologies can be used to analyze data from load cells in real-time, identifying patterns and anomalies that may indicate issues with the measurement system. This can help improve the accuracy and reliability of load cells, as well as enable predictive maintenance and fault detection.

Troubleshooting Common Load Cell Issues

Despite their reliability, load cells can sometimes encounter issues that affect their performance. Troubleshooting these issues is essential for maintaining the accuracy and reliability of load cell measurements. One of the most common issues with load cells is signal drift, where the output signal gradually changes over time without any corresponding change in the applied load. Signal drift can be caused by factors such as temperature changes, mechanical wear, or electrical interference.

To troubleshoot signal drift, it is important to identify and eliminate potential sources of interference. This may involve shielding the load cell and its wiring from electrical noise, stabilizing the temperature of the environment, or checking for mechanical issues such as loose connections or worn components. Regular calibration can also help mitigate the effects of signal drift by ensuring that the load cell’s output remains accurate over time.

Another common issue with load cells is non-linearity, where the output signal does not accurately correspond to the applied load. Non-linearity can be caused by factors such as manufacturing defects, improper installation, or mechanical deformation of the load cell. To address non-linearity, it is important to ensure that the load cell is installed correctly and that it is not subjected to excessive forces or deformations. Calibration can also help correct non-linearity by adjusting the load cell’s output to match the applied load accurately.

Load cells can also experience issues with hysteresis, where the output signal depends on the history of the applied load. Hysteresis can be caused by factors such as material properties, mechanical wear, or temperature changes. To troubleshoot hysteresis, it is important to ensure that the load cell is made from high-quality materials and that it is not subjected to excessive forces or temperature fluctuations. Regular calibration and maintenance can also help reduce the effects of hysteresis.

Conclusion: The Future of Load Cells in Measurement Technology

The future of load cells in measurement technology looks promising, with ongoing innovations and advancements poised to enhance their performance and expand their applications. As industries continue to demand higher levels of precision and reliability, load cells will play an increasingly important role in ensuring accurate measurements and efficient processes. The integration of digital and wireless technologies, advanced materials, and AI-driven analytics will further elevate the capabilities of load cells, making them indispensable tools in a wide range of applications.

As technology continues to evolve, load cells will become even more versatile and adaptable, meeting the needs of emerging industries and applications. From the development of new medical devices to the advancement of manufacturing processes, load cells will continue to be at the forefront of measurement technology, providing the accuracy and reliability that industries depend on.

In conclusion, understanding load cells and their significance in precision weighing and measurement technology is crucial for anyone involved in quality control, manufacturing, or logistics. By appreciating the mechanics behind load cells, their types, applications, and the factors to consider when choosing and calibrating them, individuals and businesses can harness the full potential of these sophisticated devices. As we move forward into the future, load cells will undoubtedly continue to play a vital role in ensuring the accuracy and efficiency of various processes, driving innovation and enhancing operational effectiveness.

Ready to Find the Perfect Load Cell Solution?

Whether you’re optimizing industrial processes or ensuring precision in manufacturing, Sands Industries offers a full range of load cells, sensors, and expert support to help you succeed.

👉 Explore Our Load Cell Solutions

Visit: https://sandsindustries.com.au/load-cells-sensors/

📞 Have Questions or Need Assistance?

Talk to our team today: Contact Us

🔍 Learn more about our offerings at sandsindustries.com.au