Top-Notch Sensors and Gauges by Sands Industries: Why VPG Technology Leads the Way in Australia

In an ever-evolving technological landscape, precision and reliability stand as cornerstones for industries reliant on accurate measurements. Enter Sands Industries, a leader in the realm of sensors and gauges, harnessing the power of innovative VPG technology to set new benchmarks across Australia. With an unwavering commitment to quality and performance, Sands Industries delivers top-notch solutions tailored to meet the diverse needs of their clients. From healthcare to manufacturing, their advanced products ensure optimal efficiency and safety in every application. This article delves into the superior offerings of Sands Industries, exploring how their cutting-edge sensors and gauges are revolutionizing the industry. Join us as we uncover the reasons why VPG technology is not just leading the way but transforming the future of measurement in Australia. Whether you’re in search of unparalleled accuracy or robust durability, you’ll discover that choosing Sands Industries means opting for excellence.

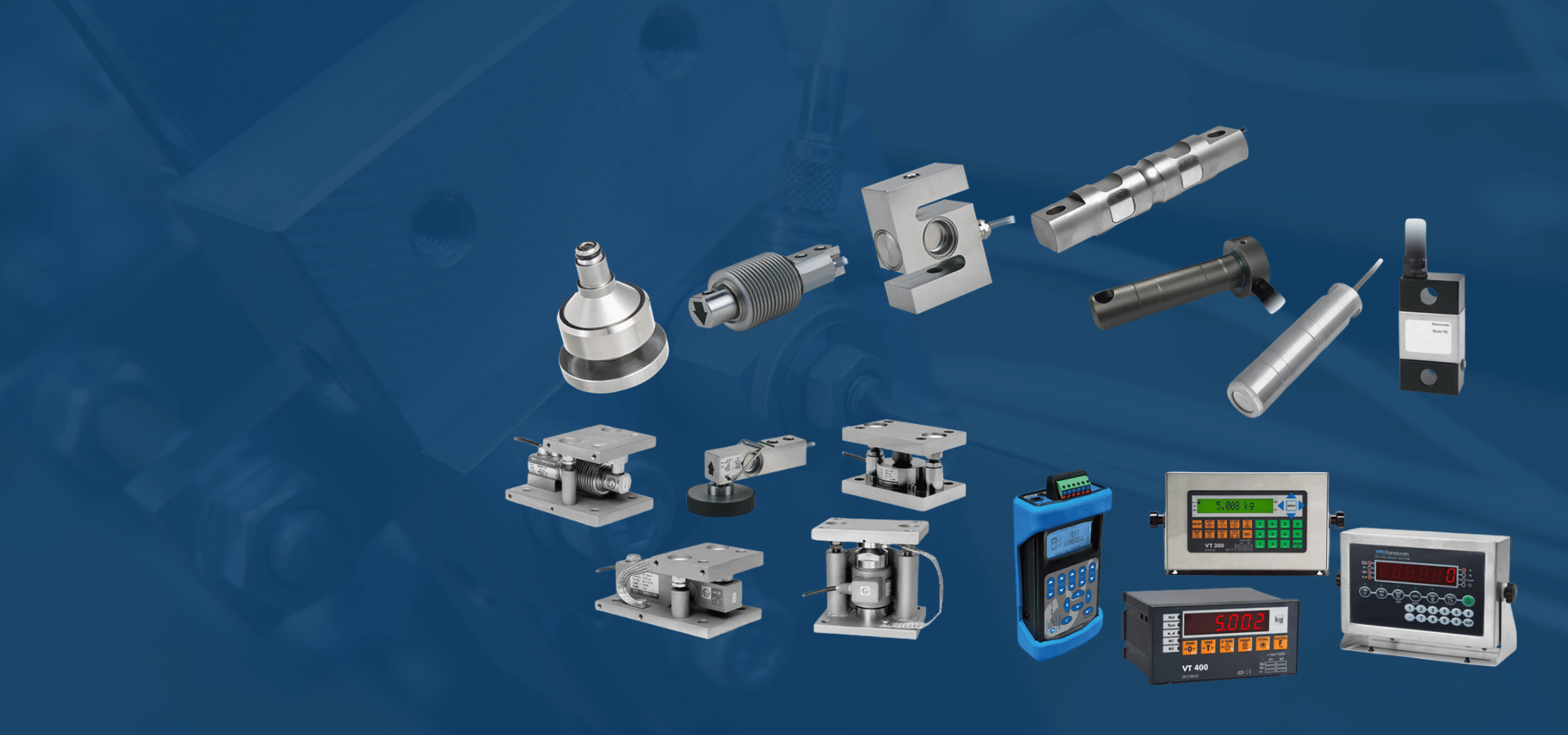

Overview of Sensors and Gauges in Industrial Applications

In the realm of industrial applications, sensors and gauges play a pivotal role in ensuring that processes run smoothly and efficiently. These devices are integral to monitoring, measuring, and controlling various parameters such as temperature, pressure, flow, and level within a system. By providing real-time data, sensors and gauges enable operators to make informed decisions, maintain optimal performance, and prevent potential issues before they escalate. The significance of these instruments cannot be overstated, as they help maintain product quality, enhance safety, and reduce operational costs across a wide range of industries.

The evolution of sensor and gauge technology has been remarkable, driven by advancements in materials science, electronics, and manufacturing techniques. Modern sensors and gauges are more accurate, reliable, and durable than ever before. They have become indispensable in sectors such as healthcare, automotive, aerospace, manufacturing, and energy, where precision and reliability are paramount. As industries continue to push the boundaries of what is possible, the demand for high-quality, innovative sensor and gauge solutions is set to grow exponentially.

Sands Industries, a leading provider of sensor and gauge technologies, has positioned itself at the forefront of this evolution. By leveraging VPG (Vishay Precision Group) technology, the company offers a range of products that set new standards in performance and reliability. In this article, we will explore the key features and advantages of VPG technology, delve into its applications across various industries, and highlight why Sands Industries is the preferred choice for clients seeking top-notch measurement solutions.

The Importance of Quality in Sensors and Gauges

Quality is a critical factor when it comes to sensors and gauges, as these instruments are often the first line of defense in detecting and addressing issues within a system. High-quality sensors and gauges provide accurate and consistent data, which is essential for maintaining the integrity of industrial processes. Inaccurate or unreliable measurements can lead to suboptimal performance, product defects, and even catastrophic failures. Therefore, investing in top-notch sensors and gauges is not just a matter of efficiency but also of safety and compliance with industry standards.

The reliability of sensors and gauges is equally important. These devices are frequently exposed to harsh conditions, including extreme temperatures, high pressures, corrosive environments, and mechanical stress. High-quality sensors and gauges are designed to withstand these conditions and continue to provide accurate measurements over their lifespan. This durability translates to lower maintenance costs, reduced downtime, and prolonged operational efficiency. In contrast, inferior products may require frequent replacements and repairs, leading to increased operational costs and potential disruptions.

Moreover, the integration of sensors and gauges into automated systems has further underscored the need for quality. With the rise of Industry 4.0 and the Internet of Things (IoT), sensors and gauges are now part of interconnected systems that rely on real-time data to optimize processes and make autonomous decisions. Any compromise in the quality of these instruments can have a cascading effect on the entire system, undermining the benefits of automation and digitalization. Therefore, choosing high-quality sensors and gauges from reputable providers like Sands Industries is crucial for harnessing the full potential of modern industrial technologies.

Key Features of VPG Technology Sensors and Gauges

VPG technology, developed by Vishay Precision Group, represents a significant advancement in the field of sensors and gauges. One of the standout features of VPG technology is its exceptional accuracy. VPG sensors and gauges are designed to provide precise measurements with minimal error, even under challenging conditions. This high level of accuracy is achieved through the use of advanced materials and manufacturing processes, which ensure that each device meets stringent quality standards. For industries where precision is critical, such as healthcare and aerospace, VPG technology offers a reliable solution that can be trusted.

Another key feature of VPG technology is its robustness and durability. VPG sensors and gauges are engineered to withstand harsh environments, including extreme temperatures, high pressures, and corrosive substances. This durability is achieved through the use of specialized materials and protective coatings that shield the devices from damage. As a result, VPG sensors and gauges have a longer lifespan and require less frequent maintenance compared to conventional products. This robustness makes them ideal for use in demanding applications, such as oil and gas exploration, where reliability is paramount.

VPG technology also offers enhanced signal processing capabilities. VPG sensors and gauges are equipped with advanced electronics that enable them to process and transmit data more efficiently. This results in faster response times and more accurate readings, which are essential for applications that require real-time monitoring and control. Additionally, VPG technology supports a wide range of communication protocols, making it compatible with various industrial systems and networks. This versatility ensures that VPG sensors and gauges can be easily integrated into existing infrastructures, providing a seamless solution for modern industrial applications.

Advantages of Using Sands Industries Products

When it comes to selecting sensors and gauges, choosing Sands Industries products offers several distinct advantages. One of the primary benefits is the company’s commitment to quality. Sands Industries adheres to rigorous quality control processes to ensure that every product meets the highest standards of performance and reliability. This dedication to quality is reflected in the exceptional accuracy and durability of their sensors and gauges, which are built to withstand the most demanding industrial environments. By choosing Sands Industries, clients can be confident that they are investing in products that will deliver consistent and reliable performance.

Another advantage of using Sands Industries products is the company’s focus on innovation. Sands Industries leverages the latest advancements in VPG technology to develop cutting-edge sensors and gauges that address the evolving needs of their clients. This focus on innovation ensures that Sands Industries products are always at the forefront of technological advancements, providing clients with access to the most advanced measurement solutions available. Whether it’s improving accuracy, enhancing durability, or expanding compatibility, Sands Industries is committed to delivering products that push the boundaries of what is possible.

Sands Industries also offers comprehensive support and service to their clients. From the initial consultation to post-installation support, the company provides expert guidance and assistance at every stage of the process. This commitment to customer service ensures that clients receive the best possible solutions for their specific needs. Additionally, Sands Industries offers customized solutions tailored to meet the unique requirements of each client. This personalized approach ensures that clients receive products that are perfectly suited to their applications, maximizing the benefits of their investment.

Why Choose Sands Industries for Sensors & Gauges in Australia?

1. Trusted VPG Technology Partner

Sands Industries is an authorised distributor of VPG (Vishay Precision Group) – a global leader in precision measurement technologies. We bring world-class load cells, strain gauges, and force sensors to the Australian market with full technical support and reliability.

2. Local Expertise, Global Standards

With deep industry knowledge across construction, agriculture, manufacturing, and logistics, our team helps you choose the right sensor for your unique environment. We offer both off-the-shelf and tailored sensor solutions.

3. Precision That Performs

Whether it’s weighing systems, force measurement, or automation, our sensors ensure exceptional accuracy, long-term stability, and rugged durability — even in harsh Australian conditions.

4. Unmatched Support & Customisation

From product selection to after-sales support, we offer consultation, calibration, and integration services to help you get the most out of your sensor investment.

5. Fast Delivery & Nationwide Reach

We maintain ready stock of high-demand products and offer quick delivery across Australia. We also help with project sourcing, engineering support, and bulk procurement for OEMs and system integrators.

Applications of VPG Technology in Various Industries

VPG technology has a wide range of applications across various industries, thanks to its exceptional accuracy, durability, and versatility. In the healthcare sector, VPG sensors and gauges are used in medical devices and equipment to monitor critical parameters such as blood pressure, oxygen levels, and temperature. The precision and reliability of VPG technology ensure that healthcare professionals can make accurate diagnoses and provide effective treatments. Additionally, the durability of VPG sensors and gauges makes them suitable for use in harsh medical environments, such as surgical theaters and intensive care units.

In the manufacturing industry, VPG technology is used to monitor and control various processes to ensure optimal performance and product quality. VPG sensors and gauges are employed in applications such as temperature and pressure monitoring, flow measurement, and level sensing. The high accuracy and fast response times of VPG technology enable manufacturers to maintain tight control over their processes, reducing the risk of defects and improving overall efficiency. Furthermore, the robust construction of VPG sensors and gauges ensures that they can withstand the harsh conditions often encountered in manufacturing environments.

The energy sector also benefits from the use of VPG technology. In oil and gas exploration, VPG sensors and gauges are used to monitor pressure, temperature, and flow rates in drilling and production operations. The durability and reliability of VPG technology make it ideal for use in the challenging conditions of the energy industry, where equipment is often exposed to extreme temperatures, high pressures, and corrosive substances. Additionally, VPG sensors and gauges are used in renewable energy applications, such as wind and solar power, to monitor and optimize the performance of energy generation systems.

Comparing VPG Technology with Competitors

When comparing VPG technology with competitors, several key factors set it apart. One of the main differentiators is the level of accuracy that VPG technology offers. While many competitors provide sensors and gauges with acceptable accuracy, VPG technology takes it a step further by delivering exceptional precision even in the most challenging conditions. This high level of accuracy is crucial for applications where precise measurements are essential, such as in healthcare and aerospace. By choosing VPG technology, clients can be confident that they are getting the most accurate and reliable data possible.

Another factor that distinguishes VPG technology from competitors is its robustness and durability. VPG sensors and gauges are designed to withstand harsh environments and provide consistent performance over their lifespan. Many competitors’ products may not offer the same level of durability, leading to more frequent replacements and higher maintenance costs. The specialized materials and protective coatings used in VPG technology ensure that the sensors and gauges can endure extreme temperatures, high pressures, and corrosive substances, making them a more reliable and cost-effective choice for demanding applications.

VPG technology also excels in terms of signal processing capabilities. The advanced electronics integrated into VPG sensors and gauges enable faster response times and more accurate readings. This is particularly important for applications that require real-time monitoring and control. Competitors’ products may not offer the same level of signal processing efficiency, which can result in slower response times and less accurate data. Additionally, VPG technology supports a wide range of communication protocols, ensuring compatibility with various industrial systems and networks. This versatility makes VPG sensors and gauges easier to integrate into existing infrastructures compared to competitors’ products.

Customer Testimonials and Case Studies

The success of Sands Industries and their VPG technology is best illustrated through the experiences of their customers. Numerous clients have shared their positive experiences, highlighting the exceptional performance and reliability of Sands Industries products. For example, a leading healthcare provider in Australia reported significant improvements in patient outcomes after implementing VPG sensors in their medical devices. The precision and reliability of the sensors allowed for more accurate monitoring of critical parameters, enabling healthcare professionals to make better-informed decisions and provide more effective treatments.

In the manufacturing sector, a prominent automotive manufacturer turned to Sands Industries for their sensor and gauge needs. The implementation of VPG technology in their production processes resulted in a noticeable reduction in defects and improved overall efficiency. The high accuracy and fast response times of the VPG sensors allowed for tighter control over manufacturing processes, leading to higher-quality products and increased customer satisfaction. Additionally, the durability of the VPG sensors reduced the need for frequent replacements and maintenance, resulting in cost savings for the manufacturer.

The energy sector has also benefited from the use of Sands Industries products. A major oil and gas company reported enhanced performance and reliability in their drilling operations after integrating VPG sensors and gauges. The robustness of the VPG technology ensured consistent performance under extreme conditions, reducing downtime and maintenance costs. The accurate data provided by the sensors enabled the company to optimize their operations, leading to increased efficiency and productivity. These success stories demonstrate the tangible benefits that Sands Industries products bring to their clients across various industries.

Future Innovations in Sensor and Gauge Technology

As technology continues to advance, the future of sensors and gauges holds exciting possibilities. Sands Industries is at the forefront of these innovations, constantly exploring new materials, manufacturing techniques, and electronic advancements to enhance their products. One area of focus is the development of smart sensors that can provide more than just measurements. These sensors will be capable of performing self-diagnostics, detecting anomalies, and communicating with other devices to enable predictive maintenance and automated decision-making. This will further enhance the efficiency and reliability of industrial processes.

Another promising area of innovation is the integration of advanced materials into sensor and gauge design. Researchers are exploring the use of nanomaterials and other cutting-edge materials that offer superior properties such as increased sensitivity, durability, and resistance to harsh conditions. By incorporating these materials into their products, Sands Industries aims to develop sensors and gauges that can provide even more accurate and reliable data in the most demanding environments. This will open up new possibilities for applications in industries such as aerospace, where precision and durability are paramount.

The rise of the Internet of Things (IoT) and Industry 4.0 is also driving innovation in sensor and gauge technology. Sands Industries is working on developing IoT-enabled sensors that can seamlessly integrate into interconnected systems. These sensors will be capable of transmitting data in real-time to centralized monitoring systems, enabling remote monitoring and control of industrial processes. This will enhance the ability to optimize operations, reduce downtime, and improve overall efficiency. The future of sensors and gauges is undoubtedly exciting, and Sands Industries is committed to leading the way with their innovative solutions.

Conclusion: Choosing Sands Industries for Your Measurement Needs

Choosing the right sensors and gauges is crucial for ensuring the accuracy, reliability, and efficiency of industrial processes. Sands Industries, with their advanced VPG technology, offers top-notch solutions that set new benchmarks in performance and durability. By leveraging the latest advancements in materials science, electronics, and manufacturing techniques, Sands Industries delivers products that meet the highest standards of quality. The exceptional accuracy, robustness, and signal processing capabilities of VPG technology make it the preferred choice for clients across various industries.

Whether you are in the healthcare sector, manufacturing, energy, or any other industry that relies on precise measurements, Sands Industries has the expertise and products to meet your needs. Their commitment to innovation ensures that you have access to the most advanced sensor and gauge solutions available. Additionally, their comprehensive support and personalized approach ensure that you receive the best possible solutions tailored to your specific requirements. By choosing Sands Industries, you are not only investing in high-quality products but also in a partner dedicated to your success.

In an ever-evolving technological landscape, precision and reliability are more important than ever. Sands Industries, with their cutting-edge VPG technology, is leading the way in transforming the future of measurement in Australia. From unparalleled accuracy to robust durability, their sensors and gauges deliver excellence in every application. By choosing Sands Industries, you are opting for top-notch solutions that ensure optimal efficiency, safety, and performance. Discover the difference that VPG technology can make and join the growing number of satisfied clients who trust Sands Industries for their measurement needs.

🔧 Discover Precision with Sands Industries

Unlock Australia’s best-in-class VPG Technology sensors & gauges — offering unmatched accuracy, reliability, and innovation for your industrial, aerospace, or agricultural applications.

- ✅ Industry-leading vLite™ load cells for lighter, more efficient measurement solutions

- ✅ Customizable force sensors tailored to your specific engineering challenges

👉 Explore Sensors & Gauges by Sands Industries – enhanced performance awaits.

🔗 Shop Now or

📞 Contact Us to discuss your precision measurement needs.

Make precise measurement part of your success story — with Sands Industries & VPG Technology at your side.